The Evolution of Concrete Block Production

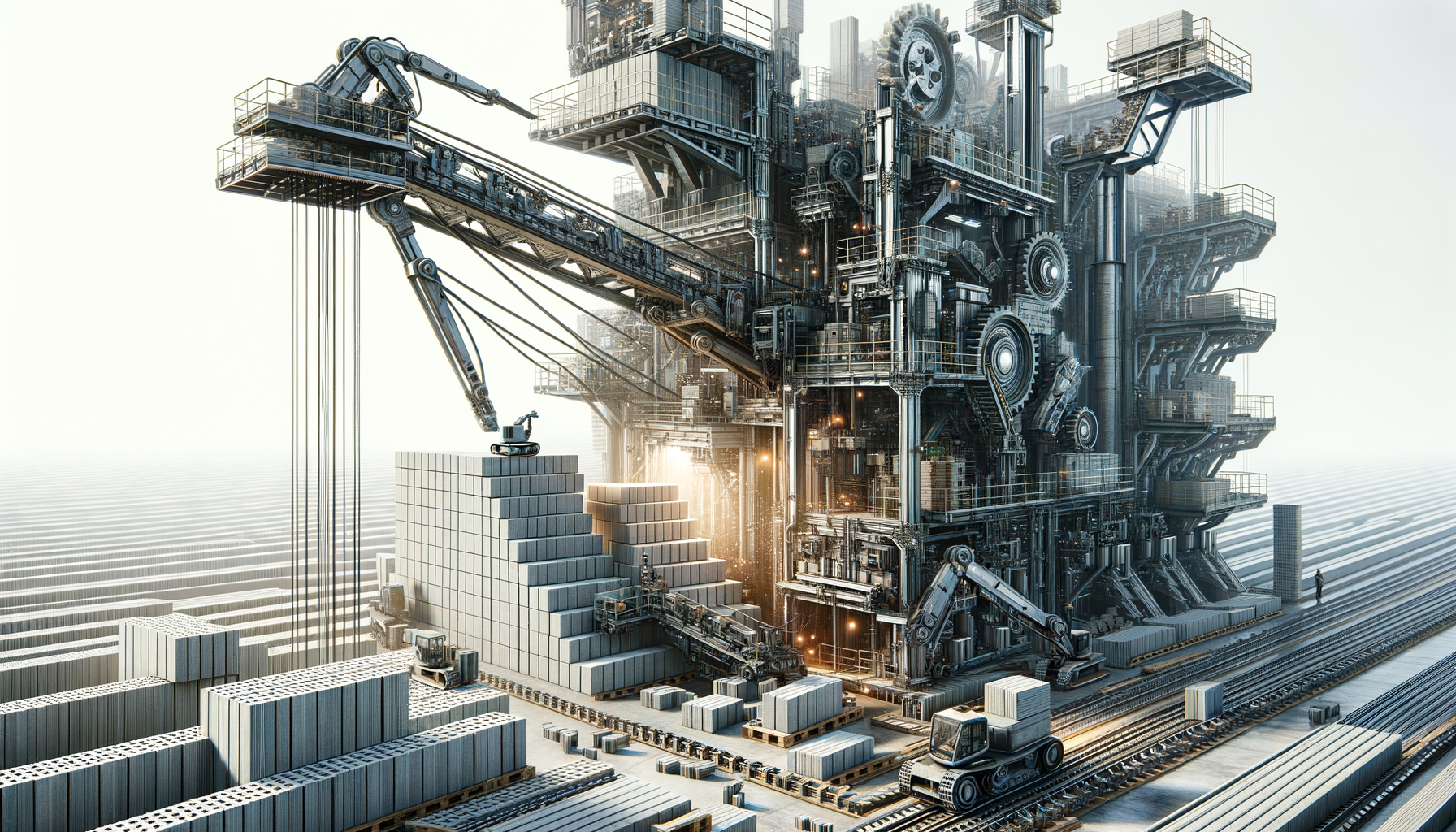

The journey of concrete block production has been marked by significant advancements, particularly with the introduction of automation. Initially, concrete blocks were produced manually, which was labor-intensive and time-consuming. The advent of automated concrete block machines has revolutionized this process, enhancing both efficiency and quality. Automation in concrete block production allows for consistent quality, as machines can mix, mold, and cure blocks with precision. This consistency is crucial for construction projects that demand uniformity and reliability in building materials.

Automated systems also significantly reduce the time required for production. For instance, what once took hours can now be completed in minutes, thanks to sophisticated machinery capable of producing thousands of blocks per day. This increase in production capacity not only meets the growing demand in the construction industry but also reduces costs, making construction projects more economical. Furthermore, automation minimizes human error, ensuring that each block meets the required standards and specifications.

In summary, the automation of concrete block production represents a pivotal shift in the construction industry, offering enhanced efficiency, quality, and cost-effectiveness. As technology continues to evolve, we can expect even more innovative solutions that will further streamline this process.

Automation in Concrete Block Production: Enhancing Efficiency and Quality

Automation in concrete block production is a game-changer for the construction industry. By integrating advanced technology into production lines, manufacturers can achieve unprecedented levels of efficiency and quality. Automated machines handle the entire production process, from mixing raw materials to curing the finished blocks. This comprehensive approach ensures that each block is produced to exact specifications, reducing waste and improving overall quality.

One of the key benefits of automation is the ability to produce high volumes of concrete blocks in a short amount of time. This is particularly beneficial for large-scale construction projects that require a steady supply of building materials. Automated systems can operate continuously, ensuring that production keeps pace with demand. Additionally, these machines are equipped with sensors and monitoring systems that detect and correct any deviations in the production process, further enhancing the quality of the final product.

Moreover, automation reduces the reliance on manual labor, which not only lowers production costs but also mitigates the risks associated with human error. This shift towards automated production is not only beneficial for manufacturers but also for builders and contractors who can rely on a consistent supply of high-quality materials. As the construction industry continues to embrace automation, we can expect even greater improvements in efficiency and quality.

Sustainability in Construction: The Role of Eco-Friendly Concrete Block Machines

Sustainability is a growing concern in the construction industry, and eco-friendly concrete block machines play a crucial role in addressing these concerns. These machines are designed to minimize environmental impact by reducing waste and energy consumption. By using sustainable materials and processes, manufacturers can produce concrete blocks that are not only durable but also environmentally friendly.

Eco-friendly concrete block machines often incorporate recycled materials into their production processes, reducing the need for virgin resources. This not only conserves natural resources but also reduces the carbon footprint associated with manufacturing. Additionally, these machines are designed to operate efficiently, using less energy and producing less waste compared to traditional methods.

Another significant advantage of eco-friendly concrete block machines is their ability to produce blocks with improved thermal properties. These blocks can help reduce energy consumption in buildings by providing better insulation, which in turn lowers heating and cooling costs. By choosing sustainable building materials, developers can contribute to a more sustainable future while also meeting the growing demand for eco-friendly construction solutions.

The Future of Concrete Block Production: Innovations and Trends

The future of concrete block production is poised for exciting developments, driven by innovations in technology and a growing emphasis on sustainability. As manufacturers continue to explore new materials and production methods, we can expect to see concrete blocks that are even more efficient and environmentally friendly.

One of the emerging trends in concrete block production is the use of alternative materials, such as industrial by-products and recycled materials. These materials not only reduce the environmental impact of production but also enhance the properties of the concrete blocks. For example, incorporating fly ash or slag into the mix can improve the strength and durability of the blocks, making them suitable for a wider range of applications.

Additionally, advancements in digital technology are transforming the way concrete blocks are produced. Smart manufacturing systems equipped with sensors and data analytics are enabling manufacturers to optimize production processes, reduce waste, and improve quality control. As these technologies continue to evolve, the concrete block industry is set to become even more efficient and sustainable.

Conclusion: Embracing Innovation and Sustainability in Construction

In conclusion, the integration of automation and sustainability in concrete block production is reshaping the construction industry. By embracing these innovations, manufacturers can produce high-quality, eco-friendly building materials that meet the demands of modern construction projects. Automation enhances efficiency and consistency, while sustainable practices reduce environmental impact and promote resource conservation.

As the industry continues to evolve, it is essential for manufacturers, builders, and developers to stay informed about the latest trends and technologies. By doing so, they can make informed decisions that not only benefit their projects but also contribute to a more sustainable future. The future of construction lies in the ability to balance innovation with environmental responsibility, and concrete block machines are at the forefront of this transformation.

Leave a Reply