Understanding Industrial Tanks: Types, Uses, and Effective Practices

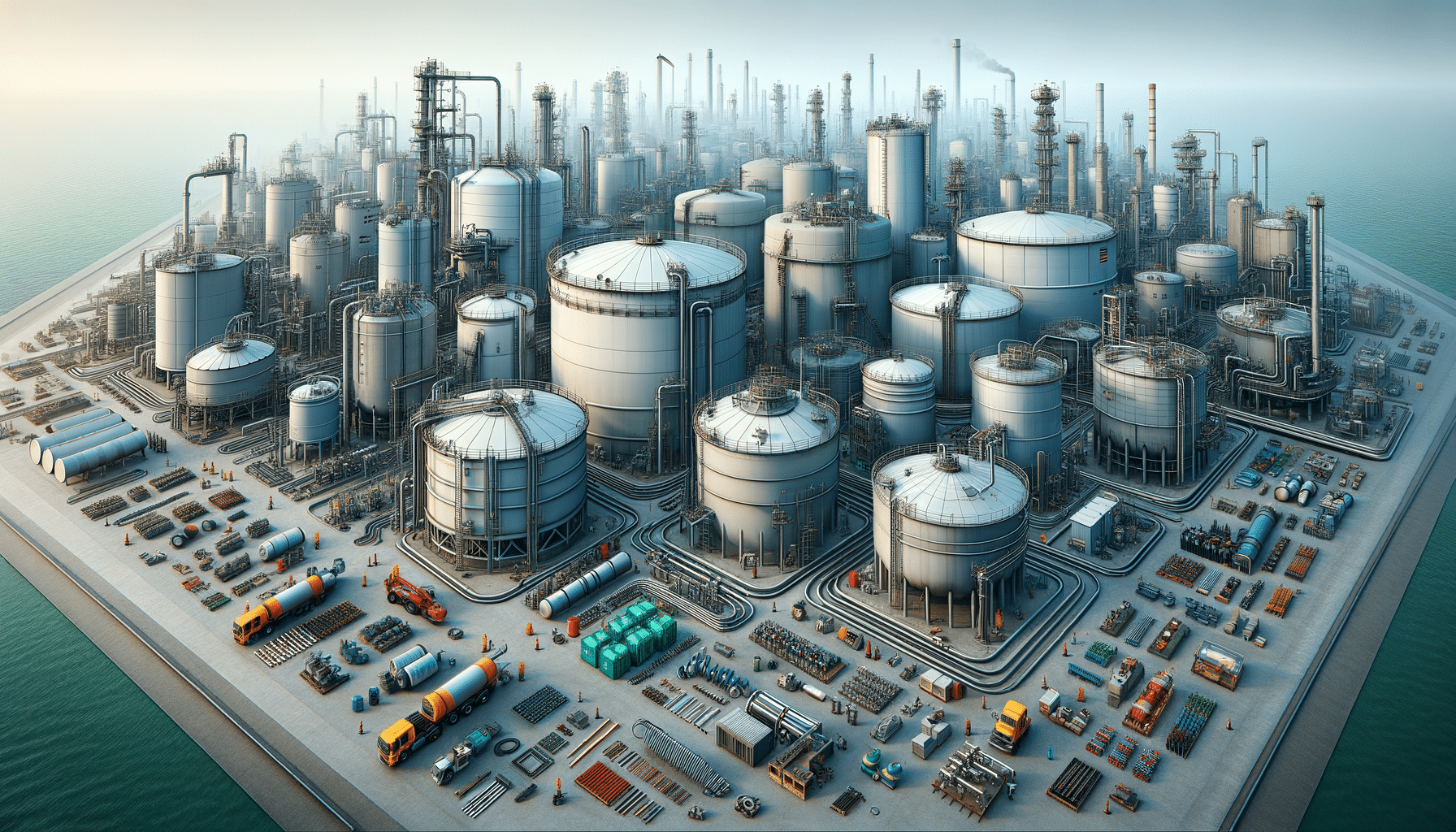

Introduction to Industrial Tanks

Industrial tanks are essential components in numerous industries, serving as storage solutions for a variety of substances. From chemicals and pharmaceuticals to food products and water, these tanks are designed to meet specific needs and ensure safe and efficient operations. Understanding the different types of industrial tanks and their applications can help businesses choose the right solution for their requirements, enhancing productivity and safety.

Types of Industrial Tanks

Industrial tanks come in various forms, each tailored to specific applications and materials. Here are some common types:

- Storage Tanks: These are used to store liquids and gases. They can be found in industries like oil and gas, water treatment, and food processing.

- Mixing Tanks: Designed for blending different substances, these tanks are prevalent in the chemical and pharmaceutical industries.

- Pressure Tanks: Used to store gases or liquids under pressure, often seen in applications involving compressed air or gas storage.

- Process Tanks: These tanks are integral to manufacturing processes, where they hold materials during production stages.

Each type of tank is constructed using materials suitable for its intended use, such as stainless steel, fiberglass, or polyethylene, ensuring durability and safety.

Applications of Industrial Tanks in Various Industries

The versatility of industrial tanks makes them indispensable across multiple sectors. In the chemical industry, tanks are used for storing and mixing hazardous substances, requiring robust materials and safety features. The pharmaceutical industry relies on tanks for precise mixing and storage of sensitive compounds, emphasizing hygiene and contamination prevention.

In food processing, tanks are essential for storing ingredients and finished products, maintaining quality and safety standards. The water treatment industry uses tanks for storing and treating water, ensuring clean and safe distribution. Each application demands specific tank features to meet regulatory and operational requirements.

The Importance of Regular Maintenance and Inspection

Regular maintenance and inspection of industrial tanks are vital for ensuring their longevity and performance. Routine checks help identify potential issues such as corrosion, leaks, or structural weaknesses, preventing costly repairs and downtime. Maintenance tasks may include:

- Inspecting for signs of wear and tear

- Cleaning to prevent contamination

- Testing for pressure and integrity

Implementing a comprehensive maintenance schedule can enhance safety, compliance, and efficiency, ultimately protecting investments and operational integrity.

Conclusion: Ensuring Optimal Performance

Industrial tanks are pivotal to the smooth operation of numerous industries. By understanding the different types, their applications, and the importance of regular maintenance, businesses can ensure these tanks perform effectively and safely. Investing in the right tank solutions and maintenance practices not only enhances productivity but also safeguards against potential hazards, making it a crucial aspect of industrial operations.