Enhancing Efficiency: The Role of Slitting Machines in Manufacturing

Introduction to Manufacturing Machine Suppliers

Manufacturing machine suppliers are pivotal in the industrial sector, providing the essential machinery needed for production processes across various industries. These suppliers offer a wide range of equipment, from basic tools to complex automated systems, ensuring that manufacturing operations run smoothly and efficiently. The selection of a reliable supplier can significantly impact the quality and efficiency of production, making it a critical decision for businesses.

Suppliers are not just vendors; they are partners in the manufacturing process. They provide technical support, maintenance services, and sometimes even training to ensure optimal use of the machinery. When choosing a supplier, companies must consider factors such as the quality of the machines, the supplier’s reputation, after-sales support, and the availability of spare parts. A well-regarded supplier can help businesses stay competitive by providing cutting-edge technology and innovative solutions.

In the current market, the demand for automated and efficient machinery is on the rise. Suppliers are adapting by offering machines that incorporate the latest technology, such as IoT capabilities and AI integration, which enhance the efficiency and productivity of manufacturing processes. These advancements not only streamline operations but also reduce costs and increase output, providing a competitive edge in the fast-paced industrial landscape.

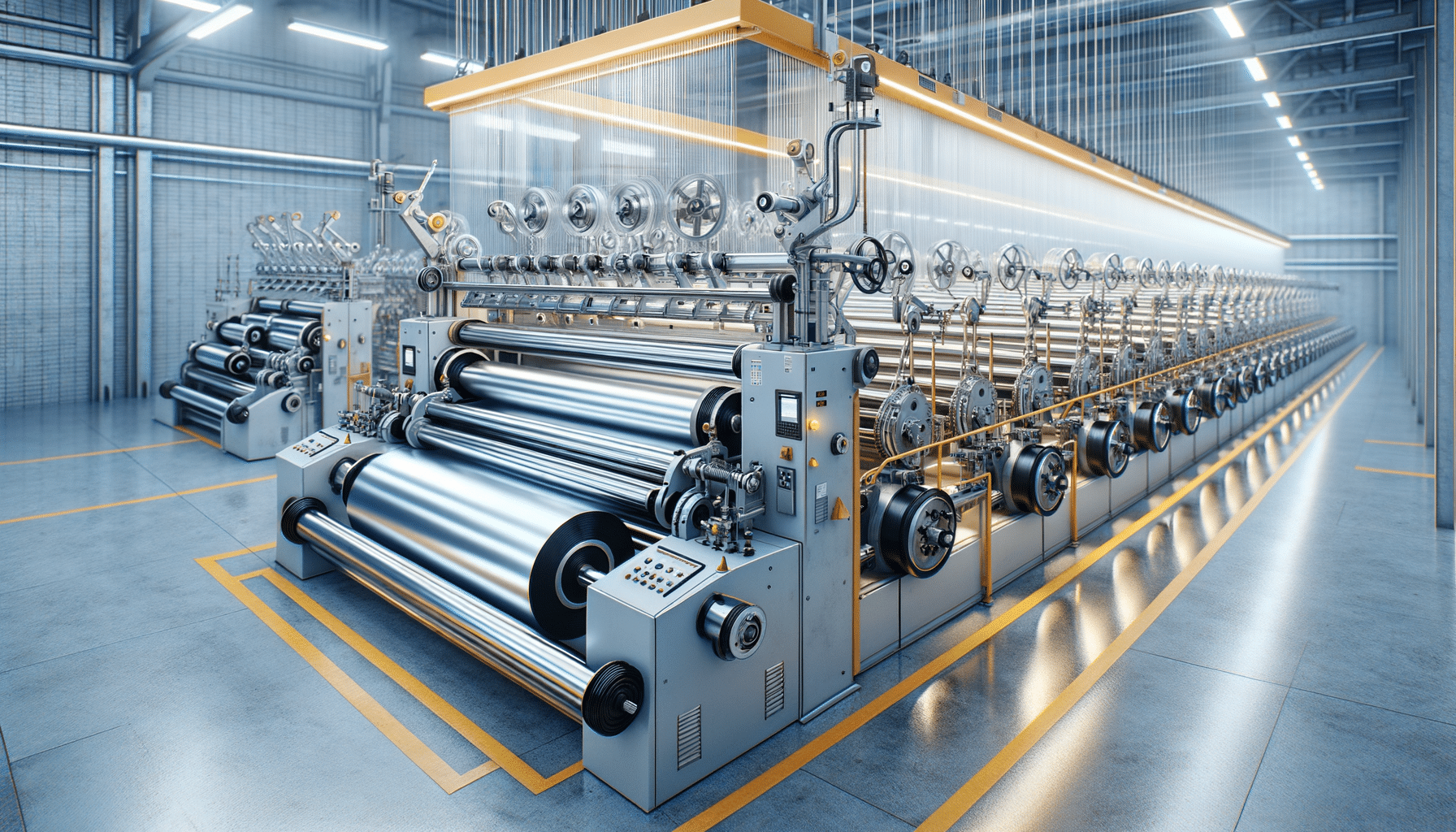

The Importance of Automatic Slitter Rewinders

Automatic slitter rewinders are essential in the manufacturing sector, particularly in industries dealing with paper, film, and foil. These machines are designed to cut large rolls of material into narrower rolls, which are then rewound for further processing or packaging. The precision and efficiency of automatic slitter rewinders make them indispensable for companies looking to optimize their production lines.

The key advantage of automatic slitter rewinders is their ability to handle large volumes of material with minimal human intervention. This automation reduces labor costs and minimizes the risk of human error, leading to higher quality outputs. Additionally, these machines are equipped with advanced features such as tension control and automatic knife positioning, which enhance their performance and reliability.

Investing in an automatic slitter rewinder can lead to substantial improvements in production efficiency. Companies can benefit from faster turnaround times, reduced material waste, and improved product consistency. As industries continue to evolve, the demand for these machines is expected to grow, driving innovation and technological advancements in their design and functionality.

Choosing the Right Slitting Machine for Your Needs

Selecting the appropriate slitting machine is crucial for any manufacturing operation. The choice depends on several factors, including the type of material being processed, the desired output size, and the production volume. It’s important to assess the specific needs of your business to ensure that the machine you choose can meet those requirements effectively.

When evaluating slitting machines, consider the following:

- Material compatibility: Ensure the machine can handle the specific materials you work with, whether it’s paper, plastic, or metal.

- Speed and efficiency: Look for machines that offer high-speed operations without compromising on quality.

- Ease of use: Machines with user-friendly interfaces and minimal setup requirements can save time and reduce the need for extensive training.

- Maintenance and support: Choose a supplier that offers robust after-sales support and maintenance services to keep your machine running smoothly.

By carefully considering these factors, businesses can select a slitting machine that not only meets their current needs but also supports future growth and expansion.

Innovations in Slitting Machine Technology

The slitting machine industry is experiencing rapid technological advancements, driven by the need for increased efficiency and precision. Recent innovations have focused on enhancing automation, improving safety features, and integrating smart technology to provide real-time monitoring and control.

One significant development is the incorporation of IoT technology, which allows machines to communicate with other devices and systems within the production line. This connectivity enables better coordination and optimization of the manufacturing process, reducing downtime and increasing overall productivity.

Another area of innovation is in the design of cutting mechanisms. Modern slitting machines are equipped with advanced sensors and precision cutting tools that ensure clean, accurate cuts with minimal material waste. These improvements not only enhance the quality of the final product but also contribute to more sustainable manufacturing practices.

As technology continues to evolve, we can expect further advancements in slitting machine design, offering even greater efficiency and versatility for manufacturers across various industries.

Conclusion: The Future of Manufacturing with Slitting Machines

Slitting machines have become a cornerstone of modern manufacturing, providing the precision and efficiency needed to meet the demands of today’s fast-paced industrial environment. As technology advances, these machines will continue to evolve, offering even greater capabilities and benefits to manufacturers.

The future of manufacturing will likely see increased integration of smart technology and automation, allowing for more streamlined operations and higher quality outputs. Companies that invest in the latest slitting machine technology will be well-positioned to stay competitive and meet the ever-changing needs of their customers.

In conclusion, slitting machines are more than just tools; they are essential components of a successful manufacturing strategy. By understanding their capabilities and keeping abreast of technological advancements, businesses can harness their full potential to drive growth and innovation in the industry.