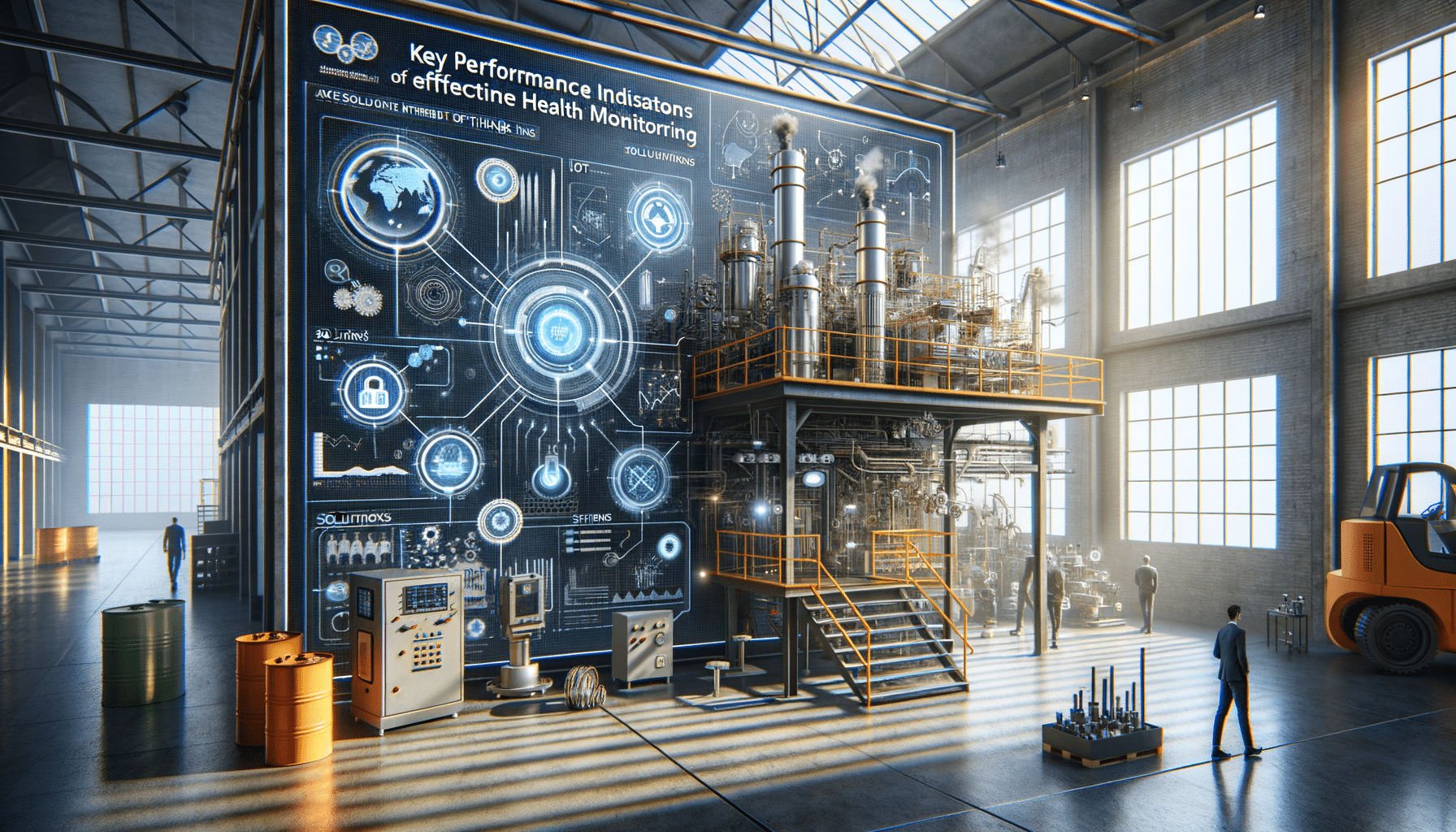

Enhancing Efficiency: Advanced Machine Health Monitoring Solutions

Introduction to Machine Health Monitoring

In the world of industrial operations, machine health monitoring plays a pivotal role in maintaining the efficiency and longevity of equipment. As industries strive to reduce downtime and optimize performance, understanding the health of machines becomes crucial. With advancements in technology, particularly the integration of IoT, the landscape of machine health monitoring has evolved significantly. This article delves into the key performance indicators (KPIs) essential for effective machine health monitoring and explores how IoT is enhancing these systems.

Key Performance Indicators for Machine Health Monitoring

KPIs are essential metrics that help in assessing the performance and health of machines. They provide valuable insights into the operational efficiency and potential issues that might arise. Some of the critical KPIs for machine health monitoring include:

- Vibration Analysis: Monitoring vibrations helps in detecting imbalances, misalignments, or bearing failures. This KPI is crucial as abnormal vibrations can indicate potential mechanical issues.

- Temperature Monitoring: Overheating can lead to severe damage. By keeping track of temperature fluctuations, operators can prevent potential breakdowns.

- Lubrication Levels: Proper lubrication is vital for smooth machine operation. Monitoring lubrication levels ensures that components are not subjected to excessive wear and tear.

- Energy Consumption: Tracking energy usage can reveal inefficiencies. Sudden spikes might indicate problems that require immediate attention.

Implementing these KPIs allows for a proactive approach to maintenance, reducing unexpected downtimes and extending the lifespan of machinery.

The Role of IoT in Enhancing Machine Health Monitoring Systems

The integration of IoT in machine health monitoring systems has revolutionized the way industries manage their equipment. IoT devices collect real-time data, providing a comprehensive overview of machine conditions. This data-driven approach enhances decision-making processes and improves operational efficiency.

IoT devices enable:

- Remote Monitoring: Operators can monitor machines from anywhere, allowing for timely interventions and reducing the need for on-site inspections.

- Predictive Maintenance: By analyzing data trends, IoT systems can predict potential failures, enabling preemptive maintenance activities.

- Data Analytics: Advanced analytics tools process vast amounts of data, identifying patterns and anomalies that might go unnoticed in traditional monitoring systems.

The role of IoT in enhancing machine health monitoring systems is undeniable, offering a more efficient and reliable approach to equipment management.

Challenges and Considerations in Implementing IoT for Machine Health Monitoring

While IoT offers numerous advantages, its implementation in machine health monitoring is not without challenges. Some of the primary considerations include:

- Data Security: With the increase in connected devices, ensuring data security and privacy becomes paramount. Industries must invest in robust cybersecurity measures to protect sensitive information.

- Integration with Legacy Systems: Many industries still rely on older machinery. Integrating IoT with these legacy systems can be complex and requires careful planning.

- Cost Implications: The initial investment in IoT infrastructure can be significant. However, the long-term benefits often outweigh these costs, making it a worthwhile investment.

Addressing these challenges is essential for the successful implementation of IoT in machine health monitoring systems.

Conclusion: The Future of Machine Health Monitoring

As industries continue to embrace digital transformation, the importance of effective machine health monitoring cannot be overstated. The integration of KPIs and IoT technologies offers a comprehensive solution for maintaining and enhancing equipment performance. By focusing on these areas, businesses can achieve greater efficiency, reduce downtime, and ultimately, improve their bottom line. The future of machine health monitoring lies in leveraging these advanced technologies to create more resilient and responsive industrial operations.