Challenges and Innovations in Membrane Bioreactor Technology

Introduction to Membrane Bioreactors

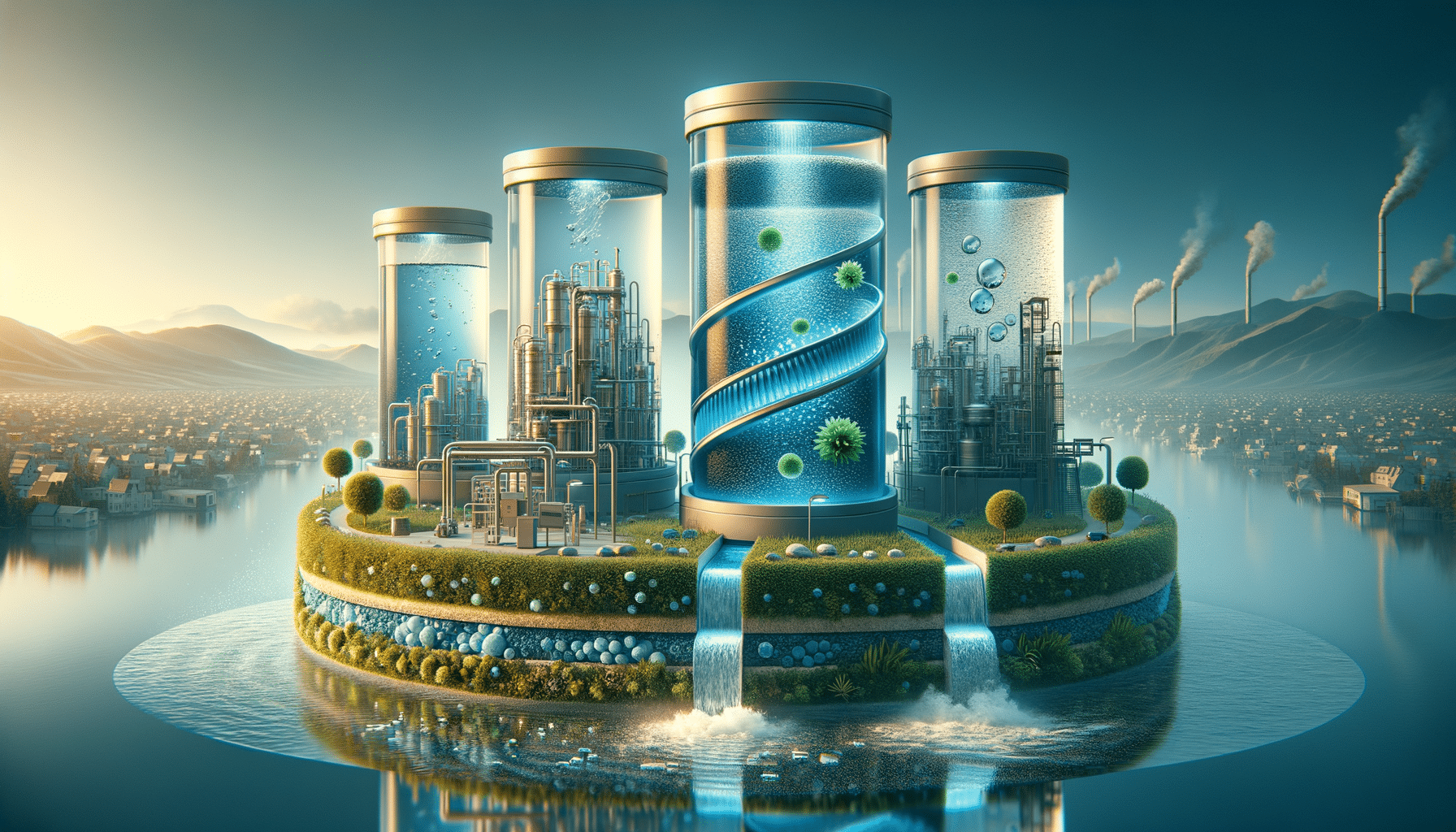

Membrane bioreactors (MBRs) have emerged as a transformative technology in the field of wastewater treatment, combining biological treatment processes with membrane filtration to create an efficient solution for water purification. This innovative approach addresses the growing need for sustainable water management solutions, especially in areas facing water scarcity and stringent environmental regulations. By integrating the benefits of biological degradation and membrane separation, MBRs offer a promising avenue for treating municipal and industrial wastewater, providing high-quality effluent suitable for various applications.

The Science Behind Membrane Bioreactor Technology

The core of membrane bioreactor technology lies in its ability to merge two distinct processes: biological treatment and membrane filtration. The biological component involves the use of microorganisms to break down organic pollutants in wastewater, a process known as biodegradation. This is followed by membrane filtration, where semi-permeable membranes are used to separate the treated water from the biomass and other particulates. The membranes employed in MBRs are typically microfiltration or ultrafiltration membranes, which allow water molecules to pass through while retaining larger particles and microorganisms. This dual-process system not only enhances the efficiency of wastewater treatment but also produces a higher quality effluent compared to conventional methods.

Advantages of Membrane Bioreactors

Membrane bioreactors offer several advantages over traditional wastewater treatment systems. One of the most significant benefits is the production of high-quality effluent that can be reused for purposes such as irrigation, industrial processes, and even potable water supply. Additionally, MBRs have a smaller footprint compared to conventional systems, making them ideal for urban areas where space is limited. They also provide greater flexibility in operation and can handle variations in influent quality and flow rates more effectively. Moreover, the enclosed nature of MBR systems reduces odor issues and minimizes the risk of pathogen release into the environment.

Challenges in Membrane Bioreactor Implementation

Despite their advantages, membrane bioreactors face several challenges that need to be addressed for widespread adoption. One of the primary issues is membrane fouling, which occurs when particles and microorganisms accumulate on the membrane surface, reducing its permeability and efficiency. This necessitates regular cleaning and maintenance, which can increase operational costs. Additionally, the initial capital investment for MBR systems is higher than that for conventional treatment plants, although this can be offset by the long-term benefits and savings in operational costs. Research and development efforts are ongoing to improve membrane materials and cleaning techniques to mitigate fouling and enhance the overall performance of MBRs.

Future Prospects and Innovations in MBR Technology

The future of membrane bioreactor technology looks promising, with ongoing innovations aimed at overcoming existing challenges and improving system efficiency. Advancements in membrane materials, such as the development of more robust and fouling-resistant membranes, are crucial for enhancing the longevity and performance of MBR systems. Additionally, the integration of advanced monitoring and control systems can optimize the operation of MBRs, ensuring consistent treatment quality and reducing energy consumption. As environmental regulations become more stringent and the demand for sustainable water management solutions grows, MBR technology is poised to play a pivotal role in addressing global water challenges.