Innovations in Wastewater Treatment: The Role of Membrane Bioreactors

The Basics of Membrane Bioreactors

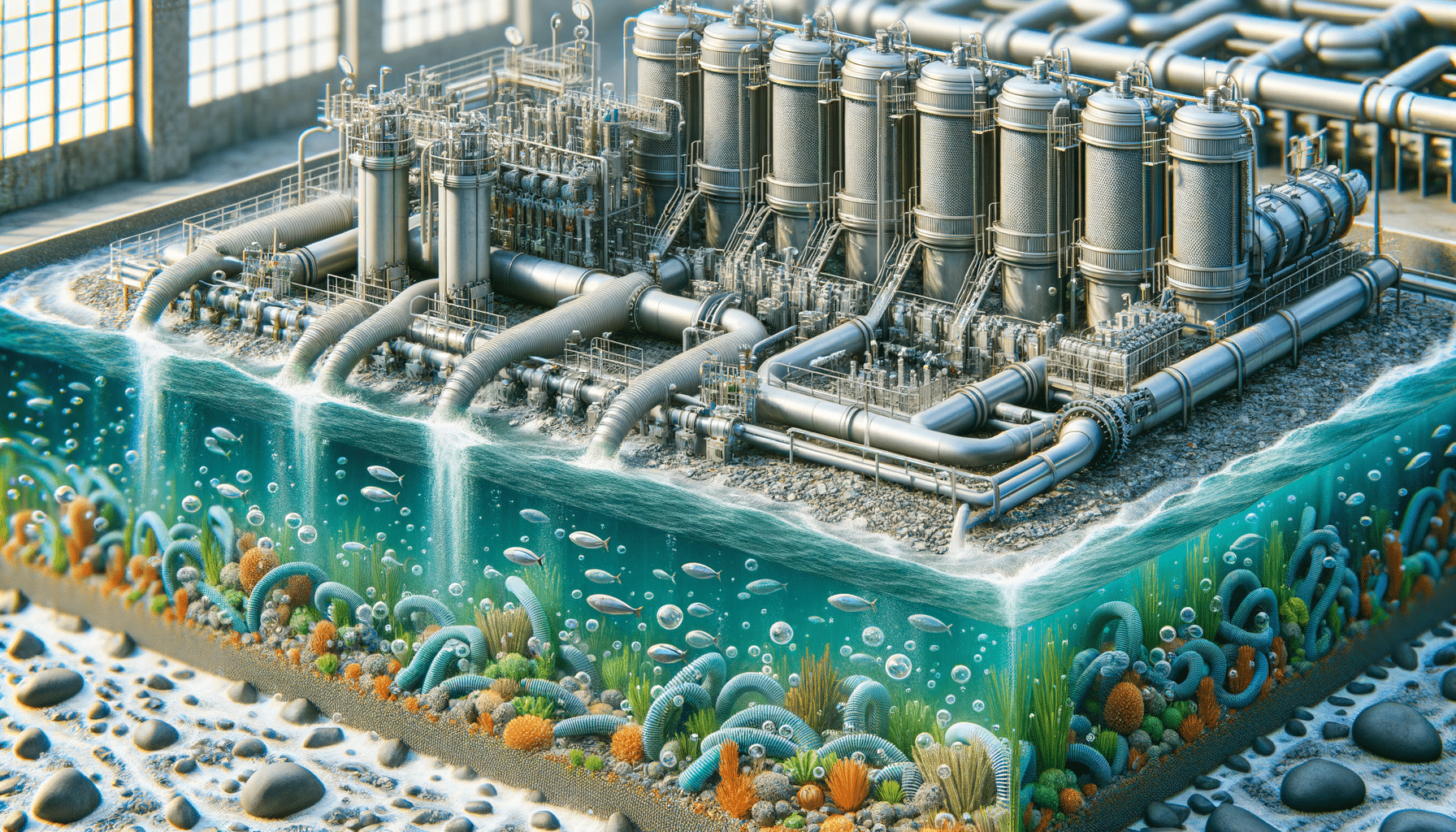

Membrane bioreactors (MBRs) have revolutionized the field of wastewater treatment by integrating biological treatment with membrane filtration. This innovative approach allows for more efficient removal of contaminants, producing high-quality effluent that can be reused in various applications. The core mechanism of MBRs lies in their ability to combine activated sludge processes with membrane filtration, which effectively separates solid waste from the treated water.

MBRs work by utilizing membranes, often made from materials like polyethersulfone or polyvinylidene fluoride, to filter out particles and microorganisms from the water. These membranes can be either flat sheet or hollow fiber configurations, each offering unique benefits depending on the specific application. The biological component of the MBR involves microorganisms breaking down organic matter in the wastewater, a process that is enhanced by the high biomass concentration maintained within the system.

One of the significant advantages of MBRs is their compact footprint compared to traditional wastewater treatment systems. This compactness is particularly beneficial in urban areas where space is limited. Additionally, MBRs offer greater flexibility in operation, allowing for adjustments in response to varying wastewater characteristics. This adaptability makes them suitable for diverse applications, from municipal wastewater treatment to industrial effluent management.

Key Advantages of Membrane Bioreactors

Membrane bioreactors offer several advantages that make them a preferred choice in modern wastewater treatment. One of the primary benefits is the production of high-quality effluent, which can be directly reused or discharged with minimal environmental impact. This is particularly important in regions facing water scarcity, where water reuse is becoming a critical component of sustainable water management.

Another advantage of MBRs is their ability to handle fluctuations in wastewater composition and volume. This resilience is due to the system’s ability to maintain high biomass concentrations, which enhances the degradation of organic pollutants. Furthermore, MBRs can effectively remove pathogens and other harmful microorganisms, ensuring that the treated water meets stringent safety standards.

In terms of operational efficiency, MBRs reduce the need for secondary clarifiers and other post-treatment processes, which are commonly required in conventional treatment systems. This reduction not only saves space but also decreases the overall energy consumption and operational costs. Additionally, the modular nature of MBR systems allows for easy scaling, making them suitable for both small-scale and large-scale applications.

Challenges in Membrane Bioreactor Technology

Despite their numerous advantages, membrane bioreactors face several challenges that must be addressed to optimize their performance. One of the primary issues is membrane fouling, which occurs when particles and microorganisms accumulate on the membrane surface, reducing its permeability and efficiency. This fouling can lead to increased operational costs due to the need for frequent cleaning and membrane replacement.

To mitigate fouling, various strategies have been developed, including optimizing the design of the membrane modules, implementing effective cleaning protocols, and using anti-fouling coatings. Additionally, advancements in membrane materials and configurations are continuously being explored to enhance fouling resistance and extend membrane lifespan.

Another challenge is the energy demand associated with membrane filtration. While MBRs are generally more energy-efficient than traditional systems, the energy required for aeration and membrane operation can still be significant. Research is ongoing to develop more energy-efficient aeration techniques and to explore the potential of alternative energy sources, such as solar or biogas, to power MBR systems.

Innovations in Membrane Bioreactor Technology

Recent innovations in membrane bioreactor technology have focused on enhancing system efficiency and sustainability. One promising development is the use of hybrid MBR systems, which combine membrane filtration with other advanced treatment processes, such as advanced oxidation or adsorption. These hybrid systems can achieve higher removal efficiencies for specific contaminants, such as pharmaceuticals and personal care products, which are challenging to remove using conventional methods.

Another area of innovation is the development of novel membrane materials with improved properties. Researchers are exploring the use of nanotechnology to create membranes with enhanced permeability, selectivity, and fouling resistance. These advanced membranes could significantly improve the performance and longevity of MBR systems, reducing operational costs and increasing their viability for widespread adoption.

Furthermore, the integration of smart technologies, such as real-time monitoring and automated control systems, is transforming the way MBRs are operated. These technologies enable operators to optimize system performance, respond quickly to changes in wastewater characteristics, and reduce the risk of operational issues. As digital technologies continue to evolve, they are expected to play an increasingly important role in the management of MBR systems.

Future Prospects and Conclusion

The future of membrane bioreactor technology looks promising, with ongoing research and development efforts aimed at overcoming current challenges and enhancing system efficiency. As water scarcity becomes a more pressing global issue, the demand for sustainable and efficient wastewater treatment solutions is expected to grow. MBRs, with their ability to produce high-quality effluent and adapt to varying conditions, are well-positioned to play a significant role in meeting this demand.

However, for MBRs to reach their full potential, continued innovation and collaboration between researchers, industry, and policymakers are essential. By addressing the challenges of membrane fouling, energy consumption, and system scalability, MBRs can become a cornerstone of sustainable water management strategies worldwide.

In conclusion, membrane bioreactors represent a significant advancement in wastewater treatment technology, offering numerous benefits over traditional systems. With ongoing innovations and a focus on sustainability, MBRs are poised to become a key component of the global effort to ensure clean and safe water for all.