Leading Innovation: Top Turbine Manufacturers Transforming Energy Production

The Future of Renewable Energy: Innovations by Leading Turbine Manufacturers

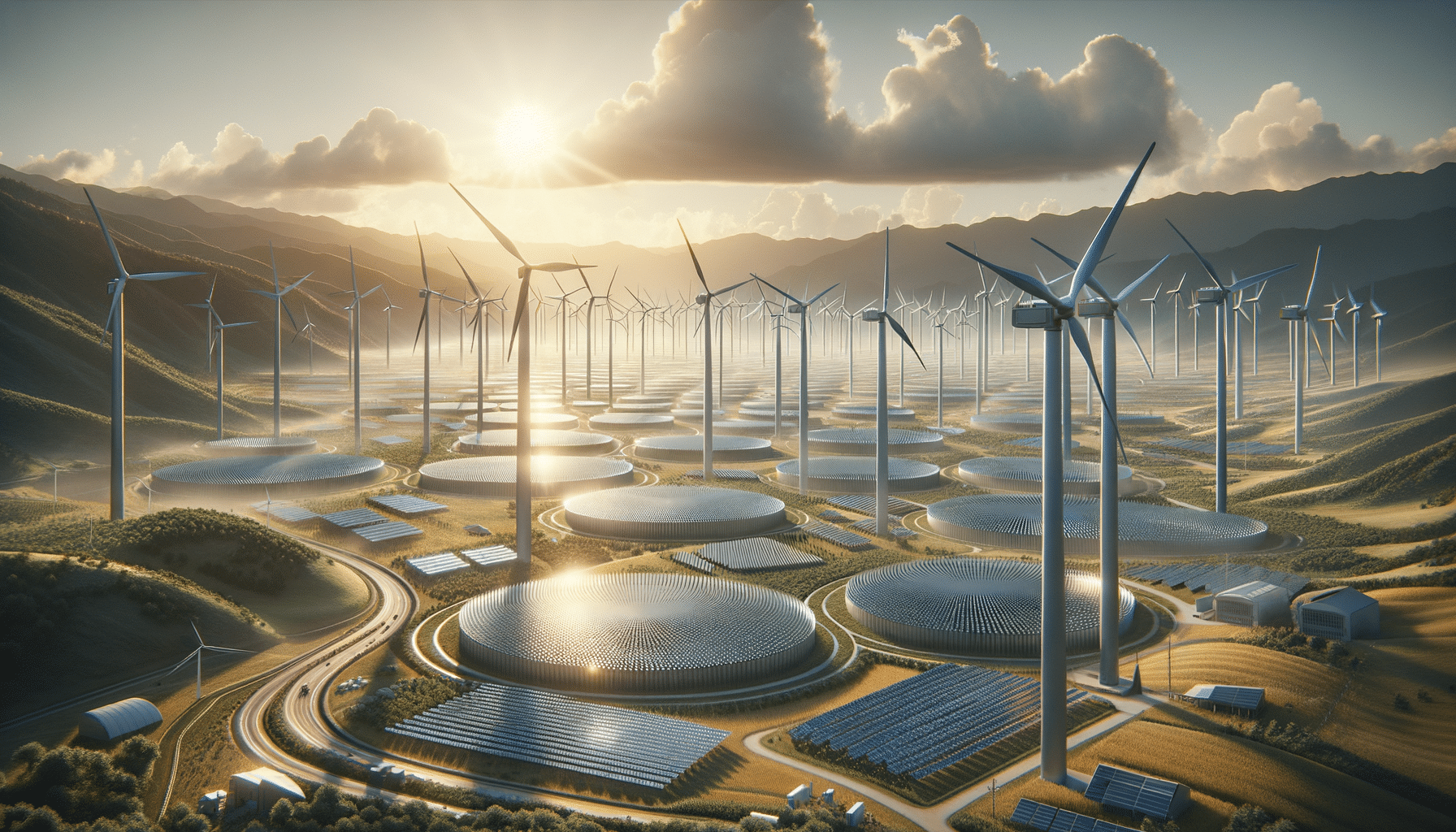

As the world pivots towards sustainable energy solutions, renewable energy has emerged as a pivotal player in the global energy landscape. Turbine manufacturers are at the forefront of this transition, driving innovation and efficiency in energy production. The advancements in turbine technology are not only enhancing energy output but also reducing the environmental footprint of energy generation. These innovations are crucial as they align with global goals to mitigate climate change and reduce reliance on fossil fuels.

Leading turbine manufacturers are deploying cutting-edge technologies to improve turbine efficiency and reliability. For instance, advancements in aerodynamics and materials science have led to the development of lighter, more durable turbine blades that can capture more wind energy. Additionally, digital technologies such as artificial intelligence and machine learning are being integrated into turbines for real-time monitoring and predictive maintenance, ensuring optimal performance and reducing downtime.

Furthermore, the rise of offshore wind farms represents a significant opportunity for renewable energy expansion. Offshore locations offer stronger and more consistent wind patterns, which can be harnessed by advanced turbine designs. Manufacturers are innovating with floating turbine structures that can be installed in deeper waters, thus expanding the potential for renewable energy production.

These innovations are not just limited to wind energy. In the realm of hydroelectric power, turbine manufacturers are developing more efficient turbines that can generate electricity from low-flow water sources, thus opening up new possibilities for hydroelectric power in regions previously deemed unsuitable.

Challenges and Opportunities in the Turbine Manufacturing Industry

The turbine manufacturing industry, while brimming with opportunities, also faces a myriad of challenges. One of the primary challenges is the high initial cost of turbine production and installation. Despite the long-term benefits of renewable energy, the upfront investment can be a barrier for many stakeholders. However, as technology advances and economies of scale are realized, these costs are expected to decrease, making renewable energy more accessible.

Another challenge is the regulatory landscape, which can vary significantly across regions. Manufacturers must navigate a complex web of regulations and standards, which can impact the design, production, and deployment of turbines. However, this also presents an opportunity for manufacturers to collaborate with policymakers to establish frameworks that support innovation and growth in the renewable energy sector.

Furthermore, the industry must address the challenge of supply chain disruptions, which can affect the availability of critical components. By investing in local manufacturing capabilities and diversifying supply chains, turbine manufacturers can mitigate these risks and ensure a steady production flow.

Despite these challenges, the turbine manufacturing industry is poised for growth. The increasing demand for clean energy solutions presents a significant opportunity for manufacturers to expand their market reach and develop innovative products that meet the evolving needs of the energy sector.

Technological Advancements in Turbine Design

Technological advancements in turbine design are revolutionizing the way energy is produced and consumed. Turbine manufacturers are leveraging state-of-the-art technologies to enhance the performance and efficiency of turbines. One notable advancement is the use of composite materials in turbine blades, which reduces weight while increasing strength and durability. This allows turbines to capture more energy, even in low-wind conditions.

Moreover, the integration of smart sensors and IoT technology into turbines is transforming maintenance practices. These technologies enable real-time data collection and analysis, allowing for predictive maintenance that minimizes downtime and extends the lifespan of turbines. This proactive approach not only improves efficiency but also reduces operational costs.

In addition to material and digital innovations, manufacturers are exploring new turbine configurations and designs. Vertical-axis wind turbines, for example, offer a compact and efficient alternative to traditional horizontal-axis designs. These turbines can be installed in urban environments where space is limited, thus expanding the potential for renewable energy generation in densely populated areas.

These technological advancements are driving the evolution of the turbine manufacturing industry, positioning it as a key contributor to the global transition towards sustainable energy solutions.

Sustainability and Environmental Impact of Turbine Manufacturing

Sustainability is at the core of the renewable energy sector, and turbine manufacturers are committed to minimizing the environmental impact of their operations. This commitment is reflected in the adoption of sustainable manufacturing practices and the development of eco-friendly turbine designs.

Manufacturers are increasingly using recycled materials in turbine production, reducing waste and conserving natural resources. Additionally, advancements in manufacturing processes have led to more efficient use of materials, further minimizing environmental impact.

The environmental benefits of renewable energy turbines extend beyond their production. By generating clean energy, turbines significantly reduce greenhouse gas emissions and air pollution, contributing to a healthier environment. Moreover, the use of renewable energy reduces reliance on fossil fuels, which are associated with environmental degradation and climate change.

However, the industry must also address the environmental challenges associated with turbine decommissioning and disposal. Manufacturers are exploring ways to recycle and repurpose turbine components at the end of their lifespan, thus ensuring a circular economy in the renewable energy sector.

Overall, the commitment to sustainability and environmental responsibility is driving innovation and growth in the turbine manufacturing industry, making it a key player in the global effort to combat climate change.

The Role of Policy and Regulation in Shaping the Future of Turbine Manufacturing

Policy and regulation play a crucial role in shaping the future of the turbine manufacturing industry. Governments around the world are implementing policies to promote the adoption of renewable energy and support the growth of the turbine manufacturing sector. These policies include financial incentives, such as tax credits and subsidies, which make renewable energy projects more economically viable.

Regulations also set standards for turbine design, production, and deployment, ensuring that manufacturers adhere to safety and environmental guidelines. These standards are essential for maintaining public trust and ensuring the long-term sustainability of the industry.

However, the regulatory landscape can also pose challenges for manufacturers. Navigating the complex web of regulations across different regions can be a daunting task, requiring significant resources and expertise. To overcome these challenges, manufacturers must engage with policymakers and industry stakeholders to advocate for policies that support innovation and growth in the renewable energy sector.

In conclusion, policy and regulation are integral to the development of the turbine manufacturing industry. By fostering a supportive regulatory environment, governments can help drive innovation and investment in renewable energy, paving the way for a sustainable and prosperous future.