A Guide For Home Renovation Companies

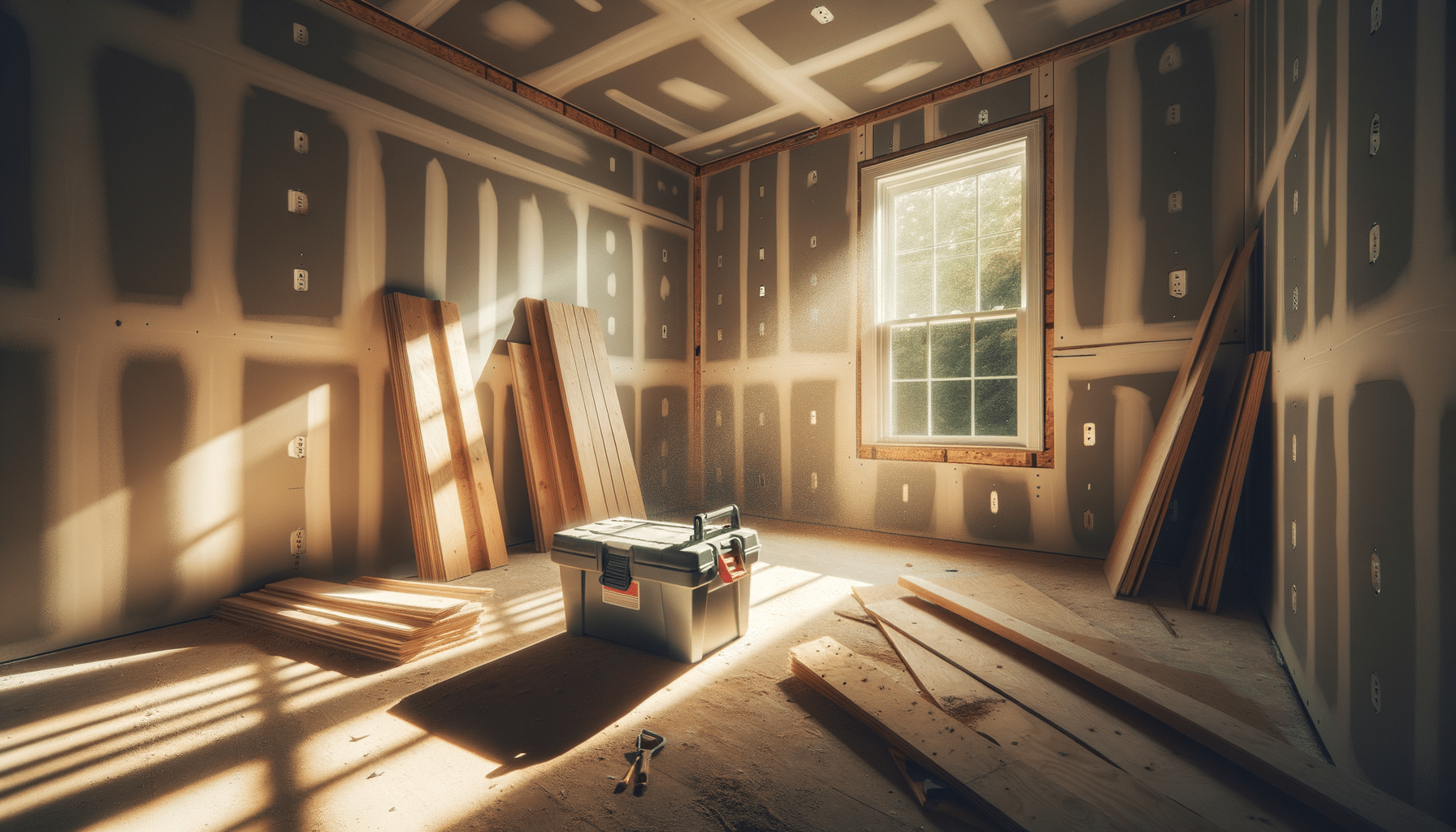

Understanding the Basics of Home Renovation

Home renovation is a transformative process that can breathe new life into old spaces. It involves modifying existing structures to improve functionality and aesthetics. The journey starts with understanding the scope of work, which might include structural changes, aesthetic updates, and functional improvements. For homeowners, it’s crucial to have a clear vision of what they want to achieve, whether it’s modernizing a kitchen, adding a bathroom, or creating an open floor plan.

Before diving into renovations, thorough research and planning are essential. Homeowners should consider their budget, the timeline, and the potential return on investment. Consulting with professionals can provide valuable insights into what is feasible within the given constraints. Additionally, it’s important to comply with local building codes and regulations, which can vary significantly depending on the location.

Overall, a successful renovation is one that meets the homeowner’s needs while enhancing the property’s market value. With careful planning and execution, home renovation can be a rewarding endeavor.

Choosing the Right Contractor

One of the most critical decisions in the renovation process is selecting the right contractor. A reliable contractor can make the difference between a smooth, successful project and a stressful, problematic one. Homeowners should start by researching potential contractors in their area and reviewing their credentials and experience.

Key factors to consider when evaluating contractors include:

- Experience and expertise in the type of renovation being planned.

- Customer reviews and ratings, which provide insights into their past performance.

- Licenses and insurance, ensuring they are legally authorized to perform the work.

- Clear communication and willingness to discuss project details and costs transparently.

It’s advisable to obtain multiple quotes and compare them to ensure competitive pricing. A good contractor will not only provide a detailed estimate but also offer guidance on the project timeline and potential challenges. By taking the time to choose the right contractor, homeowners can set the foundation for a successful renovation.

Design Trends and Ideas

Incorporating the latest design trends can significantly enhance the appeal of a renovated space. Current trends emphasize sustainability, with a focus on eco-friendly materials and energy-efficient designs. Open floor plans continue to gain popularity, promoting a sense of spaciousness and facilitating better airflow and natural light.

When considering interior home renovation projects, homeowners often explore a variety of styles, from contemporary to traditional. Mixing and matching different elements, such as textures and colors, can create a unique and personalized look. Additionally, smart home technology is becoming an integral part of modern renovations, offering convenience and increased energy efficiency.

Ultimately, the design should reflect the homeowner’s personality and lifestyle while enhancing functionality and comfort. By staying informed about the latest trends, homeowners can make choices that keep their living spaces stylish and relevant.

Budgeting and Financial Planning

Budgeting is a crucial aspect of any renovation project, ensuring that the plans are both achievable and sustainable. Homeowners should start by determining their overall budget, taking into consideration the costs of materials, labor, permits, and any unexpected expenses that may arise.

To manage costs effectively, it’s important to prioritize the most essential aspects of the renovation and be prepared to make compromises if necessary. Creating a detailed financial plan can help track expenses and prevent overspending. Additionally, exploring financing options, such as home equity loans or lines of credit, can provide the necessary funds while maintaining financial stability.

By carefully planning and managing finances, homeowners can ensure that their renovation projects are completed within budget, without sacrificing quality or scope.

Ensuring a Successful Renovation

The success of a home renovation project hinges on effective planning, execution, and management. Clear communication between homeowners and contractors is paramount, ensuring that expectations are aligned and any issues are promptly addressed. Regular progress updates and site visits can help keep the project on track and identify potential problems early.

Post-renovation, it’s important to conduct a thorough inspection to ensure that all work has been completed to a satisfactory standard. Addressing any deficiencies or unfinished tasks promptly can prevent future complications and ensure long-term satisfaction with the renovation.

In summary, a successful renovation is one that transforms a home into a more functional and aesthetically pleasing space while staying within budget and timeline constraints. With careful planning and execution, homeowners can achieve their desired outcomes and increase the value of their property.